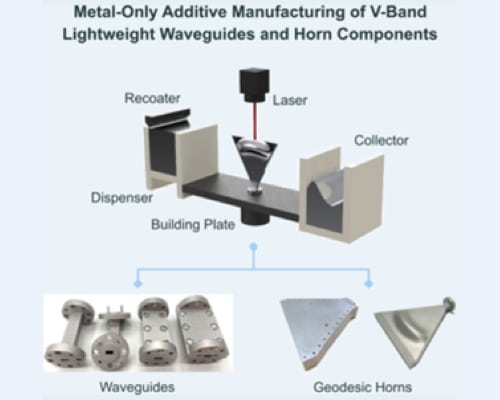

Metal-Only Additive Manufacturing of V-Band Lightweight Waveguide and Horn Components

Abstract

DOI: 10.1109/TMTT.2024.3451065

IEEEXplore: https://ieeexplore.ieee.org/document/10684995

Device

Waveguide and horn components by 3-D metal-only additive manufacturing.

Spectrum

52–68 GHz (V-band)

Novelty

Metal-only laser powder-bed fusion additive manufacturing (LPBF-AM) with AlSi10Mg aluminum alloy achieves high precision and low surface roughness. Powder layers applied 30 µm thick are fused with a laser and recoated and refused until the target thickness is achieved. Monolithic and 2-piece straight and bend waveguides horn prototypes were simulated, manufactured and measured.

Two-piece waveguide and horn prototypes were fabricated with and without electromagnetic band gap (EBG) holes in the assemblies with generally poorer performance due to the difficulty to maintain a consistent air gap during assembly, and with a significant 2x weight penalty for the waveguide and 6x weight penalty for the horn compared to the monolithic prototypes.

Application

Low cost, high performance, metal-only microwave components in the V-band

Performance

5.3 dB/m or better attenuation for monolithic straight waveguide, 8 dB/m or better attenuation for 90° E-plane monolithic waveguide bend and -30 dB |S11| from 50 to 70 GHz.

20 dBi gain at 60 GHz, 45% to 57% aperture efficiency, ≥70% radiation efficiency ≥ 80% for a monolithic 15 λ x 1 λ (at 60 GHz) H-plane horn.